We offer 2 packages without thermal stabilization: the package U and the package B.

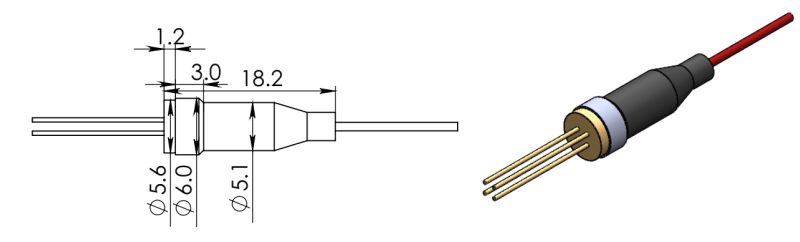

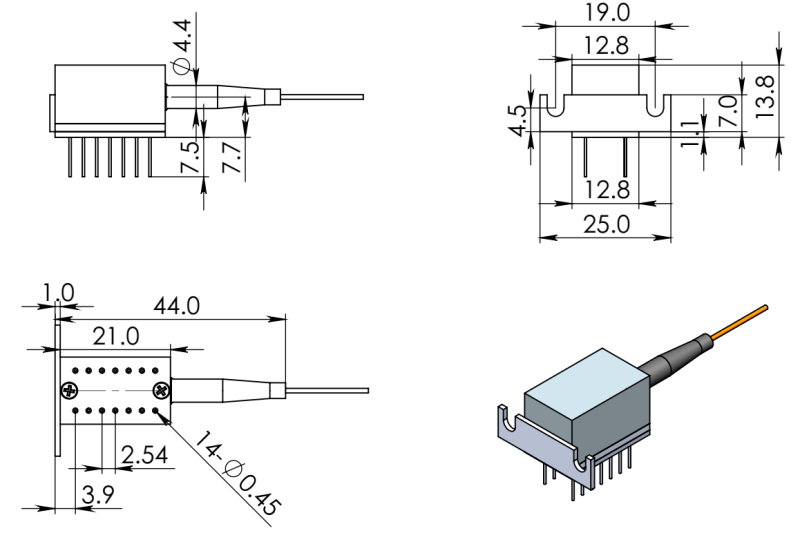

- The coaxial package U is the most compact and lightweight of our packages. It can be soldered into a PCB without any mount. One should keep in mind laser diode (LD) self-heating upon operation. Thus, the coaxial package U is suitable for pulse mode LD operation only.

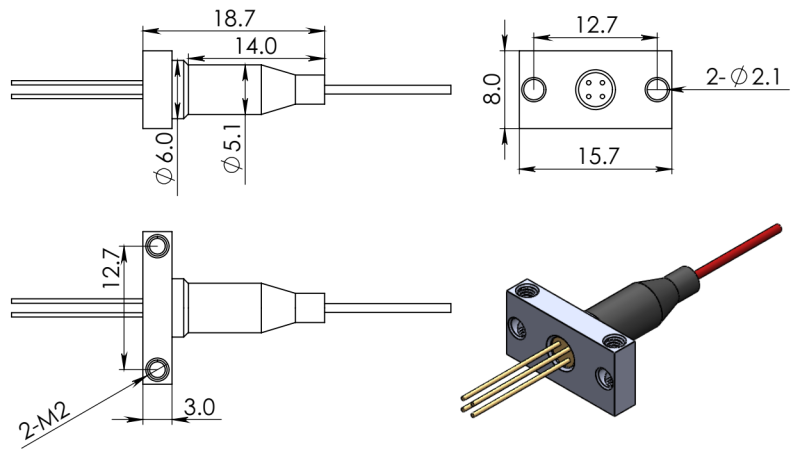

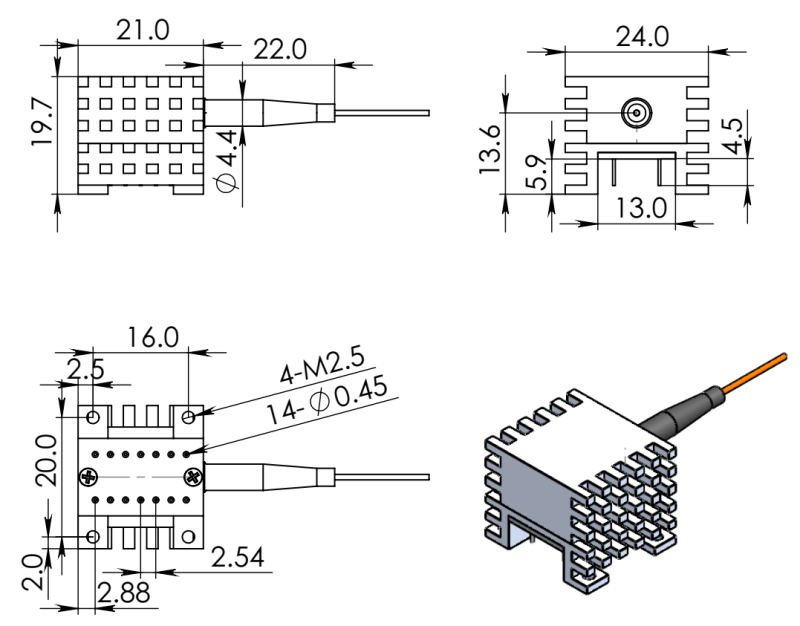

- The coaxial package with a bracket B is also a package without active thermal stabilization. It includes a bracket for convenient mounting. There are threaded holes on the top and bottom sides and holes on the front side (for panel mount) of the bracket for mounting to a PCB or a heat sink.

We offer 2 packages with active thermal stabilization: the package T and the package E. There are a thermistor and a TEC in these packages.

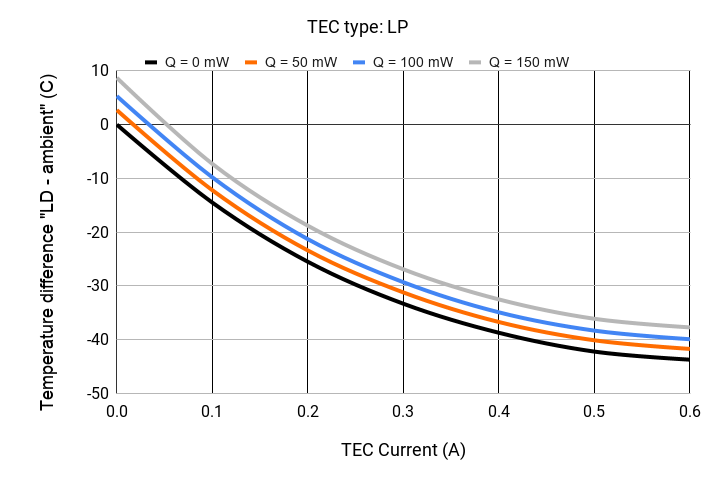

We offer the modules with 2 types of TECs.

- For the smaller-power laser diodes with the released heat up to 250-300 mW we offer TEC type LP (Imax =0.7 A, Umax = 3.9 V, Qmax = 1.4 W, AC R = 4.7 Ohm, dTmax = 72 K).

- For the laser diodes with larger heat release we offer TEC type HP (Imax =1.4 A, Umax = 3.9 V, Qmax = 3.3 W, AC R = 2.0 Ohm, dTmax = 69 K).

The thermistor for temperature measuring is an NTC thermistor with the parameters: R0 = 10 kOhm @ 25C, B = 3600 K.

The performance of the packages T and E with the LP-type TEC is illustrated in the figure. The experimentally measured difference between laser diode temperature and ambient temperature (radiator, 25 C) is shown for various heat load values Q=Vop*Iop-Poptical.

- The package T is the common design of DIL-14-pins package. The 7.5 mm long pins are suitable for soldering into a PCB. A laser diode and a TEC release a significant amount of heat during operation. For heat removal, the package's "wings" should be attached to a heat sink. Thermal resistance between TEC's hot side and "wings" is 2.5 K/W.

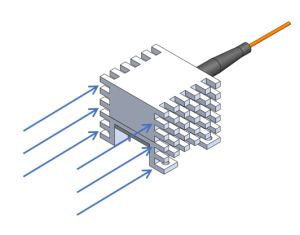

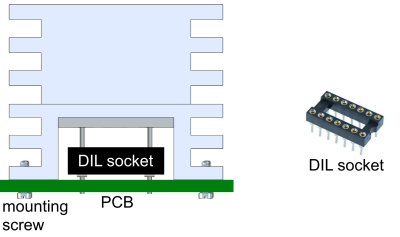

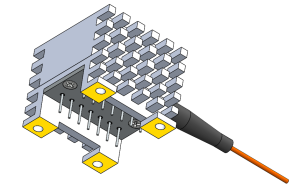

- The package E is our proprietary case developed for mounting on a PCB without soldering.

The module should be simply inserted into a DIL-14-pins socket (for example, C0110-14SAAB00R http://www.hsuanmao.com.tw/product_item.php?fcid=&cid=&id=497) and fixed with mounting screws M2.5. This allows for a quick exchange of the module.

Heat removal from the case could be done in 3 ways:

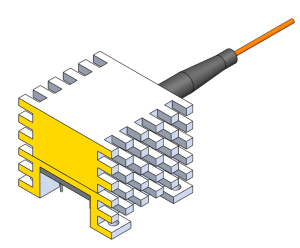

1) attaching a heat sink to the rear facet of the module (thermal resistance 2.6 K/W)

2) attaching the module's bottom "legs" to a heat sink (thermal resistance 3.1 K/W)

3) by forced air convection with a small fan (estimated thermal resistance 11 K/W at the airflow speed 30 cm/s)